Wanted: Faster Print Times

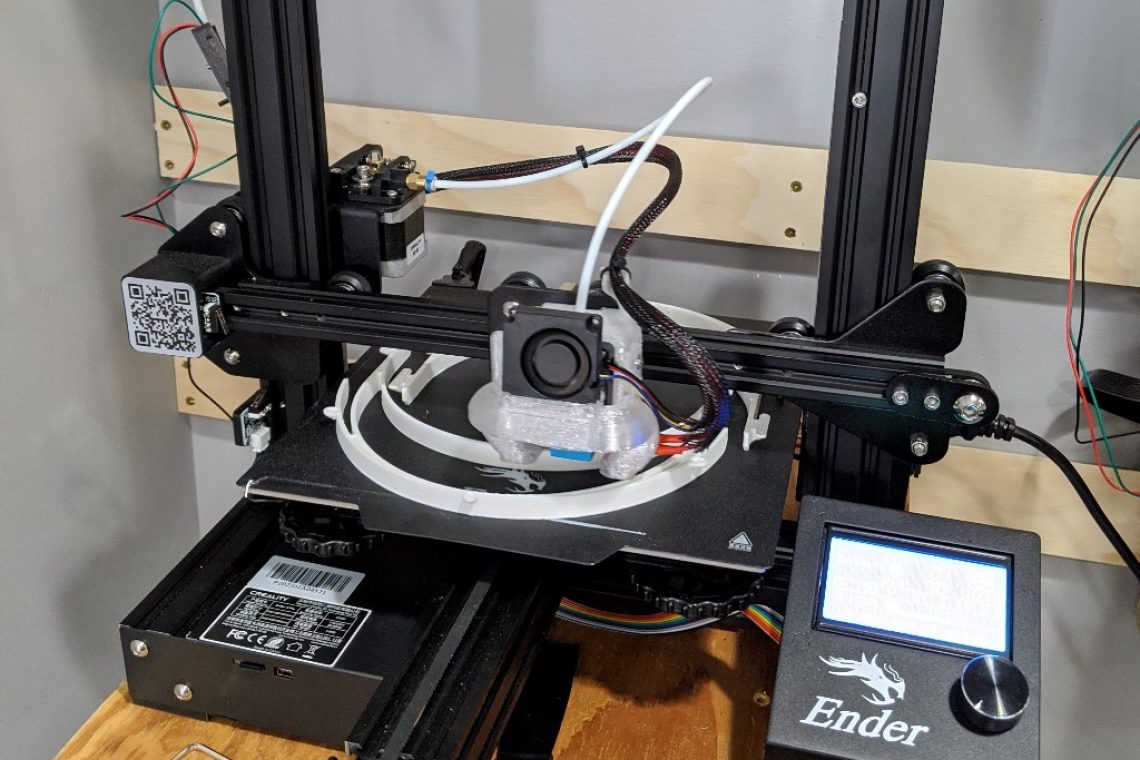

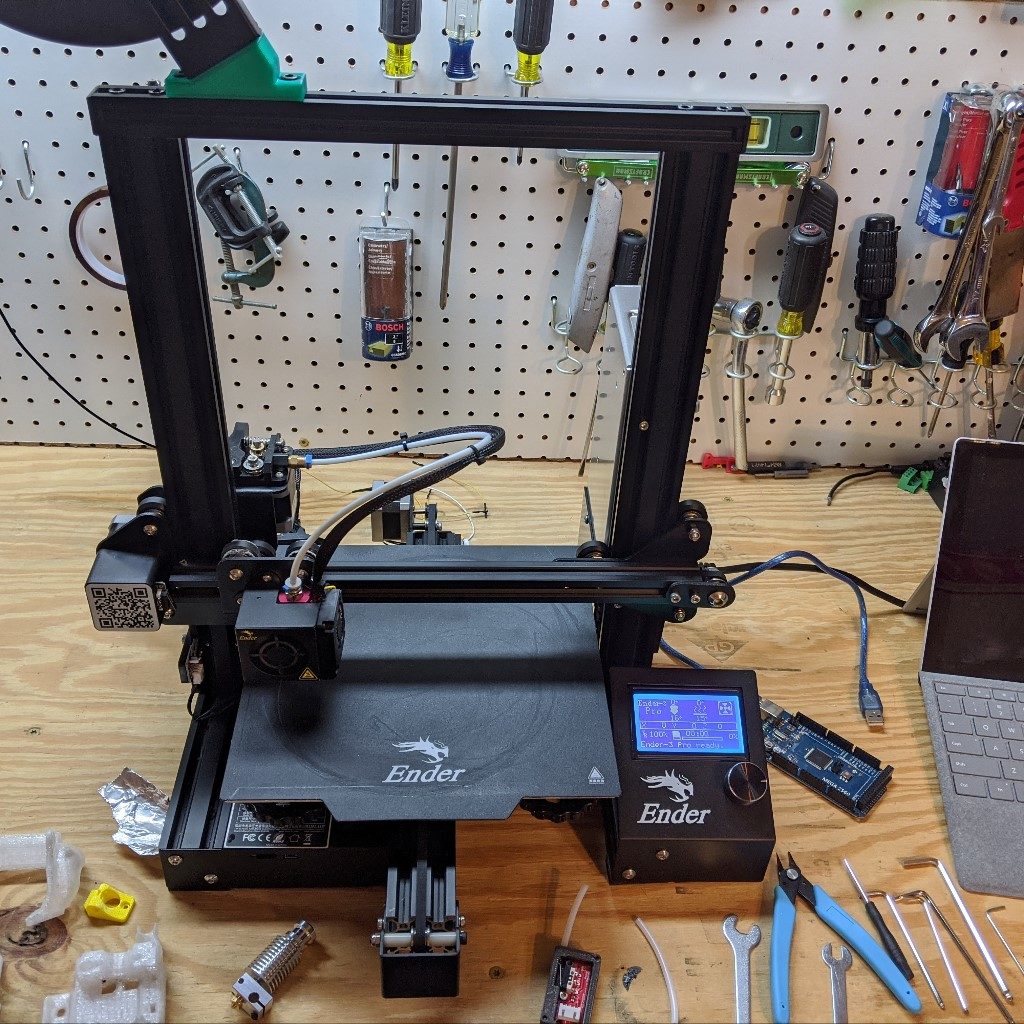

My friend Dan picked up several Ender 3 3D Printers in late March 2020 to help fight COVID-19, and I volunteered to run two of them to create face shields for health care workers and first responders. The filament of choice is PETG, which requires a hot end temperature of 235 to 260 degrees C. Creality sells the stock hot end that comes on the Ender 3 as the popular style where the PTFE tube runs all the way through the melt zone and butts up against the nozzle. This design works very well for filaments with lower working temperatures, mainly PLA and ABS. While it is safe to operate the hot end at 240C, this is the low end of the PETG workable temperature range, and I found it to be a rate limiting factor when trying to cut down print times. Also of note, is that these are structural parts that do not require any detail. My solution was to replace the Ender 3 stock hot end with the popular E3D V6 all metal hot end, and use a 0.8mm nozzle to speed print times up. The following is a step by step account of my upgrade, with pictures.

Table of Contents

Tools and Printed Parts

I used the allen wrenches that came with the Ender 3, a razor knife, an E3D V6 hot end with bowden, an 0.8mm nozzle, and the printed parts for a Bullseye hotend conversion, found here:

https://www.thingiverse.com/thing:2759439

I selected the Bullseye design because it allowed me to reuse all of the stock fans, heater cartridge, and thermistor. More on that later.

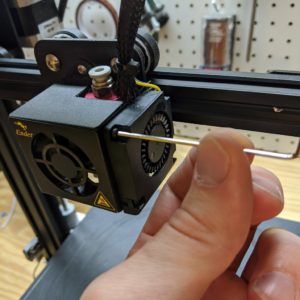

Removing The PTFE Tube

It is common for plastic to have melted inside the hot end, between the PTFE tube and the nozzle, which makes removing the tube at room temperature extremely difficult. I pre heated the nozzle to ABS, since I had been using PETG.

Using the wrench supplied, I carefully removed the nozzle. I used a pair of pliers for the last few turns, to make sure I didn’t drop it.

Rather then fight pulling the PTFE tube up through the heat break, I pushed it through the bottom of the hot end and cut off the melted plastic covered part with a razor knife.

Next I pulled the PTFE tube out of the hot end. This was much easier than trying to fight pulling it out with melted plastic all over the bottom of the tube. I was careful not to touch the end, as it was hot still.

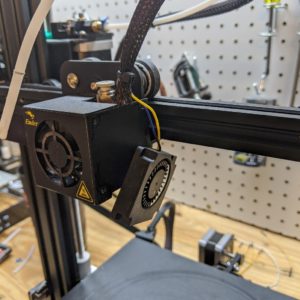

Removing The Fans and Shroud

With the hot end cool, and the printer off, first remove the part cooling fan. I set the screws and fan duct aside for now.

Remove the two screws holding the shroud on to the x carriage.

I removed the heatbreak fan by unscrewing the four screws holding it to the shroud. I set the screws and shroud aside for now.

Removing The Hot End

I loosen the set screw holding the heater cartridge in, and loosen the screw holding in the thermistor in place. I then gently and carefully pull them out of the hot end.

I remove the two screws holding the heatbreak to the x carriage. I set the screws and hot end aside for now.

Installing The Bullseye Base

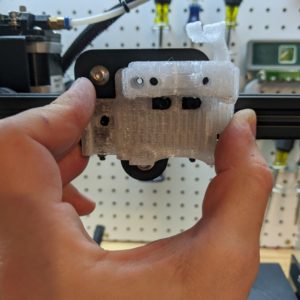

At this point I cleaned up any strings and blobs/zits I had on my printed parts. I also made sure the captive nuts stayed in place, and that the bolts had clearance where they needed to. Also that the E3D V6 fit snugly in the groove mount.

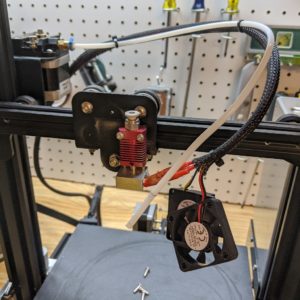

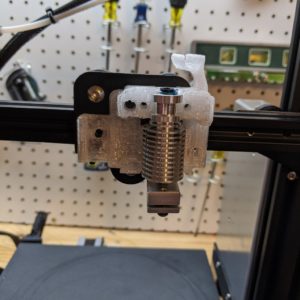

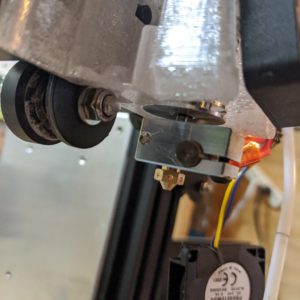

I made sure that the base mount lined up with the mounting hole location on the Ender 3 X carriage before fastening. Then I installed the E3D V6 in the groove mount, making sure the side with the heater cartridge was facing me.

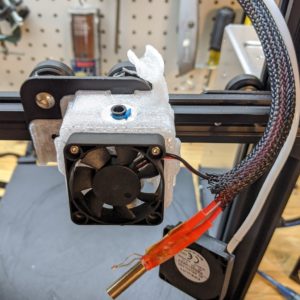

Next I installed the other half of the base, making sure the heatbreak was snug. Then I cut two of the zip ties on the wire, so that I could move the protective sheath back. I then fastened the heatbreak fan to the base using two of the screws that formerly held it to the shroud. It is important to know that the fan will blow air in the direction of the sticker, so I made sure to point the sticker side towards the heat break.

Installing The Heater Cartridge And Thermistor

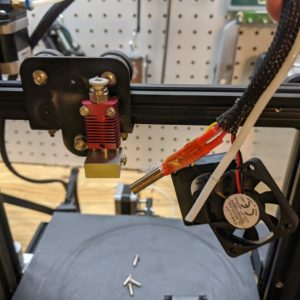

I Installed the heater cartridge, while making sure that the thermistor was able to make it inside the hot end as well. I tightened the set screw on the heater cartridge.

So I have had previous experiences with older printers using these glass bead NTC thermistors, as opposed to the cartridge style provided by e3d, and the results are that the temperature control is very inconsistent. Air does not conduct heat very well, so my solution is to gently pack tin foil into the cavity which will provide much more consistent themperature readings.

Next I put the cute little silicone sock on the hot end. I wish these were customize-able, you could have an ugly christmas sock contest.

Installing The Part Cooling Fan

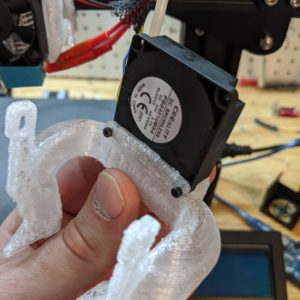

I used two of the original part cooling fan screws to secure the fan to the Bullseye duct. It was important to do this step now, as the bolts are not accessible once the duct is installed.

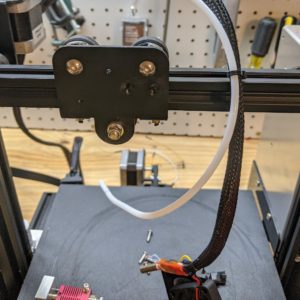

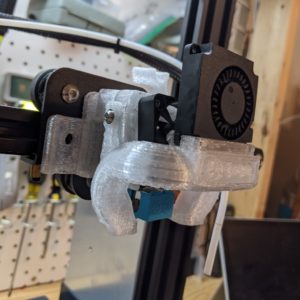

Next I installed the Fan Duct onto the base. I kept the screws loose so that I could set the height.

I made sure there was some clearance between the bottom of the nozzle and the fan duct before tightening the screws securing the fan duct.

Lastly I reinstalled the bowden tube, and put the clip back on to secure it.

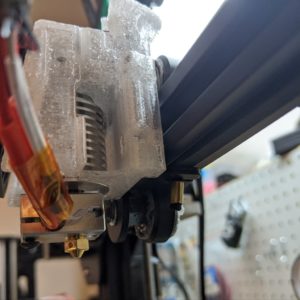

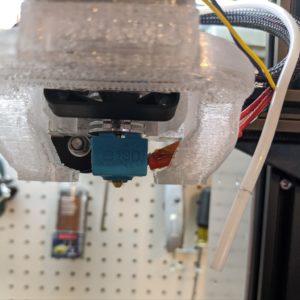

Install Complete!

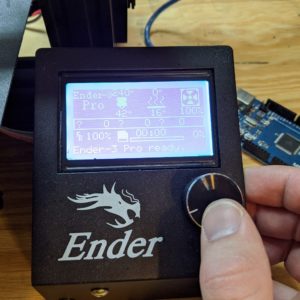

I have now fully completed the installation of the Bullseye hot end using the E3D V6. I have been successful with decreasing my print times using this new setup. My previous print time for two Prusa RC3 style headbands was around 6 hours using the stock hot end. With the upgraded hot end I am able to produce two headbands in about three hours, and I think I can improve on that eventually.

As a talking point, I realize that a more simple solution exists in the microswiss all metal hot end upgrade that is made specifically for the Ender 3, and that particular upgrade does not involve changing any of the stock fan shrouds or ducts. I chose not to go that route because I have experience with the E3D products, and like to keep all of my machines running as many of the same components as possible.

I am aware that this is a $75 upgrade for a $200 printer, but in this specific case, all of the 3D printers have been sold out in stores and online for at least two weeks, and this upgrade is a reliable way to double my throughput.

I hope you enjoyed reading this post, and some of you found this useful. Please feel free to leave any comments or feedback!

Thank you